In the HVAC Coil Manufacturing Industry there are primarily three types of manufacturers – OEM, Air Handler, and Custom. Which you use depends largely on your application and the reliability needed, but only one provides the perfect fit and capacity every time.

OEM Coil Manufacturers build coils specifically for equipment with larger production runs. Because of the large volume, production efficiency reduces overall costs so they are an ideal fit for manufacturing companies installing coils in their equipment.

Air Handler Manufacturers typically design and build coils for their own equipment. In the event that they have extra capacity they will build coils for other companies, however their first priority is to their own manufacturing needs.

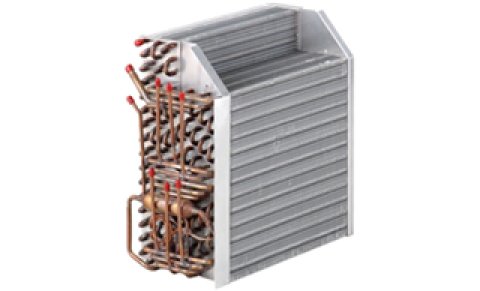

Custom Coil Manufacturers are an ideal fit for many HVAC situations. The coils are custom built to nearly any type and capacity to fit your precise replacement or new design needs. We know that there are several custom coil manufacturers out there. Through Campbell-Sevey, our customers have access to both plate-fin HVAC and heavy-duty coil designs.

Modine is a top tier provider of custom-designed and built coils for the industrial and commercial heating, cooling, air conditioning, ventilation, and refrigeration markets. Their ability to offer heating and cooling coils for indoor comfort as well as building heat recovery for energy savings allows them to create the right coil solution for our customers’ applications. They are also highly responsive in cases where quick manufacturing is needed. They can, and do, build custom coils in 48 hours when needed.

Armstrong’s heavy duty coil division is a great solution for industrial or power plant applications. Whether it’s combustion air preheat for large boilers, high temperature product processes, or spray dryer applications where plate fin coils would experience inadequate discharge temperatures or premature failure, they have the proper materials and construction methods to build the heaviest duty coils on the market. They understand appropriate internal circuiting construction methods for steam coils to prevent freezing and water hammer that would lead to premature failure.

At Campbell-Sevey, we also size inlet piping, strainers, control valves, steam traps (for steam heating), vacuum breakers, check valves, and outlet piping to operate properly together. We take responsibility for the whole package.

Get the solution that best fits your needs

At Campbell-Sevey, we work directly with you to determine your needs and provide solutions that best fit your requirements. To learn more contact the team at Campbell-Sevey.

In the HVAC Coil Manufacturing Industry there are primarily three types of manufacturers – OEM, Air Handler, and Custom. Which you use depends largely on your application and the reliability needed, but only one provides the perfect fit and capacity every time.

OEM Coil Manufacturers build coils specifically for equipment with larger production runs. Because of the large volume, production efficiency reduces overall costs so they are an ideal fit for manufacturing companies installing coils in their equipment.

Air Handler Manufacturers typically design and build coils for their own equipment. In the event that they have extra capacity they will build coils for other companies, however their first priority is to their own manufacturing needs.

Custom Coil Manufacturers are an ideal fit for many HVAC situations. The coils are custom built to nearly any type and capacity to fit your precise replacement or new design needs. We know that there are several custom coil manufacturers out there. Through Campbell-Sevey, our customers have access to both plate-fin HVAC and heavy-duty coil designs.

Modine is a top tier provider of custom-designed and built coils for the industrial and commercial heating, cooling, air conditioning, ventilation, and refrigeration markets. Their ability to offer heating and cooling coils for indoor comfort as well as building heat recovery for energy savings allows them to create the right coil solution for our customers’ applications. They are also highly responsive in cases where quick manufacturing is needed. They can, and do, build custom coils in 48 hours when needed.

Armstrong’s heavy duty coil division is a great solution for industrial or power plant applications. Whether it’s combustion air preheat for large boilers, high temperature product processes, or spray dryer applications where plate fin coils would experience inadequate discharge temperatures or premature failure, they have the proper materials and construction methods to build the heaviest duty coils on the market. They understand appropriate internal circuiting construction methods for steam coils to prevent freezing and water hammer that would lead to premature failure.

At Campbell-Sevey, we also size inlet piping, strainers, control valves, steam traps (for steam heating), vacuum breakers, check valves, and outlet piping to operate properly together. We take responsibility for the whole package.

Get the solution that best fits your needs

At Campbell-Sevey, we work directly with you to determine your needs and provide solutions that best fit your requirements. To learn more contact the team at Campbell-Sevey.What Type of Manufacturer Should You Use for Heating and Cooling Coils?