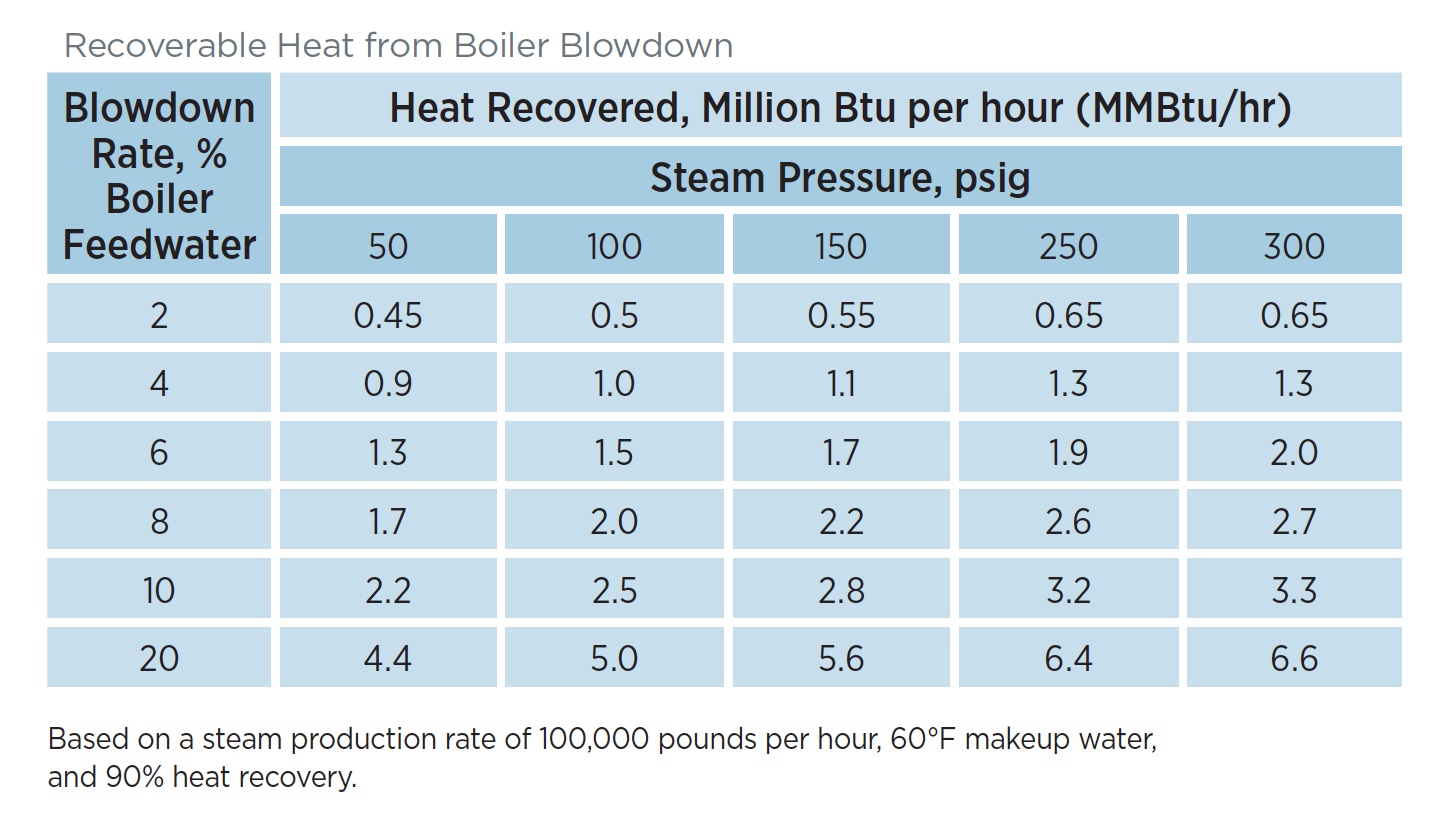

Heat can be recovered from boiler blowdown by using a heat exchanger to preheat boiler makeup water. Any boiler with continuous blowdown exceeding 5% of the steam rate is a good candidate for the introduction of blowdown waste heat recovery. Larger energy savings occur with high-pressure boilers. The following table shows the potential for heat recovery from boiler blowdown.

Example: In a plant where the fuel cost is $8.00 per million Btu ($8.00/MMBtu), a continuous blowdown rate of 3,200 pounds per hour (lb/hr) is maintained to avoid the buildup of high concentrations of dissolved solids. What are the annual savings if a makeup water heat exchanger is installed that recovers 90% of the blowdown energy losses? The 80% efficient boiler produces 50,000 pounds per hour (lb/hr) of 150-pounds-per-square-inch-gauge (psig) steam. It operates for 8,000 hours per year. The blowdown ratio is:

Blowdown Ration = 3,200 ÷ (3,200 + 50,000) = 6.0%

From the table, the heat recoverable corresponding to a 6% blowdown ratio with a 150-psig boiler operating pressure is 1.7 MMBtu/hr. Since the table is based on a steam production rate of 100,000 lb/hr, the annual savings for this plant are:

Annual Energy Savings =

[1.7 MMBtu/hr x (50,000 lb/hr/100,000 lb/hr) x 8,000 hr/yr]/0.80 = 8,500 MMBtu

Annual Cost Savings =

8,500 MMBtu/yr x $8.00/MMBtu = $68,000

Blowdown Energy Recovery: Blowdown waste heat can be recovered with a heat exchanger, a flash tank, or flash tank in combination with a heat exchanger. Lowering the pressure in a flash tank allows a portion of the blowdown to be converted into low-pressure steam. This low-pressure steam is most typically used in deaerators. Drain water from the flash tank is then routed through a heat exchanger. Cooling the blowdown has the additional advantage of helping to comply with local codes limiting the discharge of high-temperature liquids into the sewer system.

For additional information on heat recovery, contact the team at Campbell-Sevey or download this Steam Tip sheet for suggested actions and resources.

This tip is provided by the U.S. Department of Energy – Energy Efficiency and Renewable Energy and originally published by the Industrial Energy Extension Service of Georgia Tech.